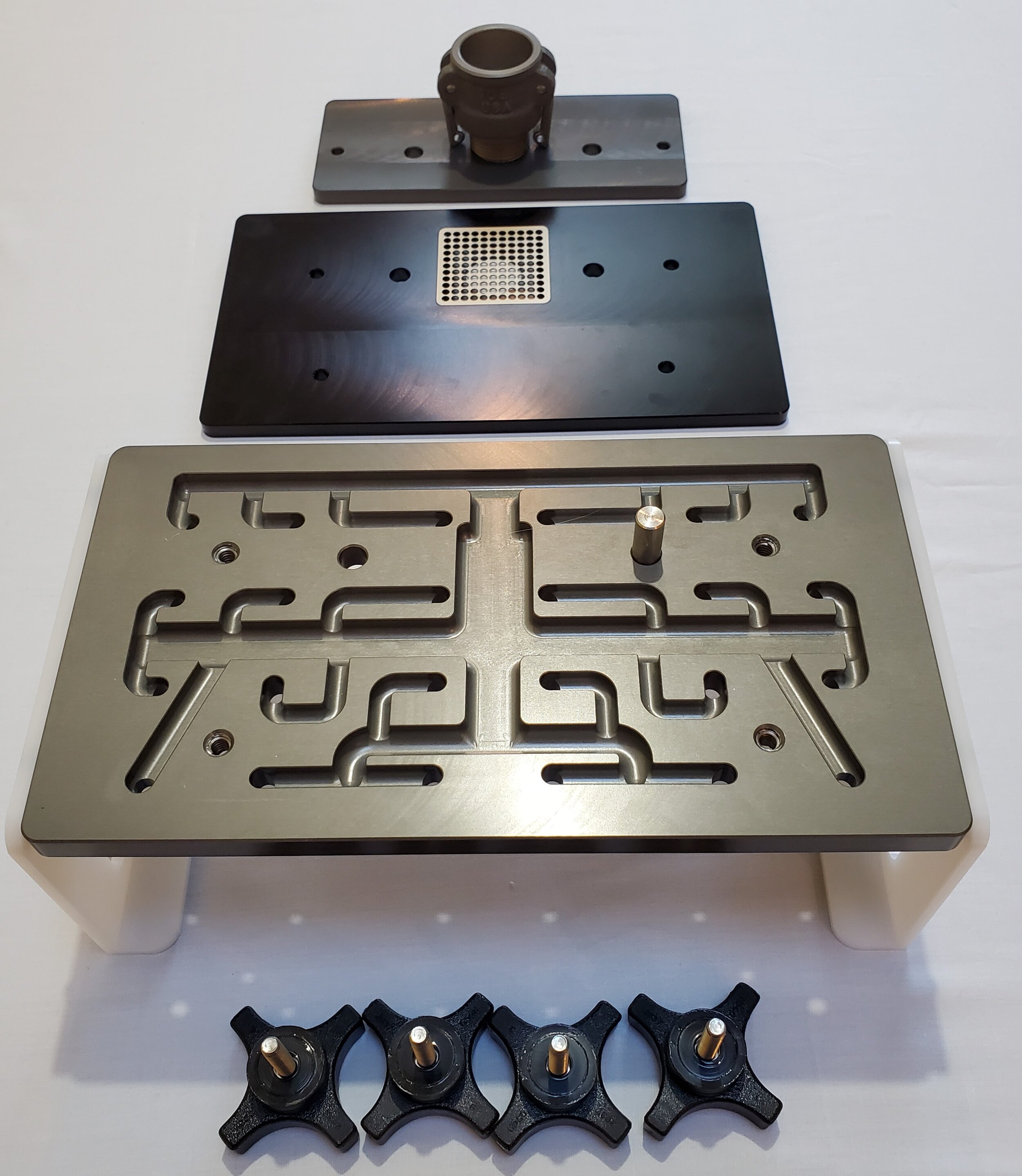

Features - Beta 1.0 Testing Unit - Standard

Patent Pending design for superior bar weight uniformity

Adjustable mold holders

Patent Pending filter design

Universal fit for any 1” Cam Lock Tempering Machine

Mold sheet width 10-3/4” +/- 1/4” (~275mm +/- 6mm)

Mold sheet position adjustment +/-11/16” (~175mm)

FE- Depositor a Brief History

In October of 2020, with the help of the team at Chequessett chocolate, I started developing the FE-depositor. The idea was to design a depositor that was engineered and engineered specifically with small batch bar makers in mind. Why? simple, I am an engineer. I work for an aerospace engineering company and we are relentless in our pursuit of providing services that are exceptional. It has taught me over the past decade that comprising on a product is unacceptable. When I saw the frustration and aggravation that the team at Chequessett chocolate experienced with the depositor they bought the gears starting spinning. At first it was a fun thought experiment to keep me busy while COVID locked the country down. I would count down the minutes till my workday ended so I could run Computational Fluid Dynamics on yes, of all things, a chocolate depositor. My weeknights were spent designing and drafting the latest revisions and my weekends were spent turning paper into prototypes in my machine shop. It had been kind of a daydream to develop it into a product I could offer. Somewhere around the 7th revision that dream started to solidify. After the incorporation of a removable filter (at the behest of Chequessett) the first working prototype became an irreplaceable part of their production line. I thought, I just spent 4 months developing this product and it works… really well, and there are some really neat features about it. So, I started Fairbank Engineering LLC, selected a manufacture to make the parts (cause mine where a little rough around the edges…literally) and just recently submitted the patent application on the design.